What is Offset Printing? Is It Better & Affordable Than Digital?

Offset printing press applying ink to paper sheets high-speed offset printing press in operation with paper moving through rollers

A vital tool for mankind for over a century, offset printing remains even in today's digital age one of the most trusted and cost-effective ways to produce high-quality print. But what exactly is offset printing? How does it compare to digital printing? And most importantly, is it right for your next project?

What is Offset Printing?

Offset printing is a traditional print method that uses metal plates to transfer ink onto paper via a rubber blanket roller. Each plate corresponds to one of the four base printing colors: Cyan, Magenta, Yellow, and Black. When layered together, these colors create sharp, vibrant images.

The term "offset" refers to the use of the rubber cylinder to transfer ink to paper. This indirect method ensures smooth coverage and unmatched precision, especially over large volumes.

How Offset Printing Works.

1. Design & Pre-Press

Once we receive your artwork or idea, whether it's a business card, brochure, or a folding carton, our Pre-Press team steps in to ensure it's print-ready. We thoroughly check the following elements:

Color settings - CMYK

Image resolution- More than 300 DPI

Margins, bleed lines, and safe zones

Typography and font embedding

We are more than happy to provide free designing & consultation on your design to ensure perfection once printed. This stage is all about ensuring accuracy before production begins.

2. Plate Making

For offset printing, we create aluminum printing plates one for each of the four CMYK colors: cyan, magenta, yellow, and black. your design will be etched onto these plates using advanced imaging systems like Computer-to-Plate (CTP).

The plates are then mounted on the press and carefully aligned to ensure pinpoint registration so that all colors layer together perfectly during printing. This precision is key to achieving rich, crisp images and smooth gradients.

3. Printing

Now comes the heart of the process. As the press begins to run

Ink from each plate is transferred to a rubber blanket, which then applies the image onto paper.

The sheets move through high-speed rollers, applying each color one by one in exact alignment.

Our offset presses are calibrated for color consistency, pressure, and ink flow throughout the print run.

This method allows us to produce hundreds and thousands of flawless copies from the first sheet to the last.

4. Finishing

After printing, your job moves into the finishing phase where it is transformed into the final product.

Depending on your needs, this may include:

Cutting, Trimming to precise sizes

Folding - bi-fold, tri-fold, gate fold

Binding - saddle stitching, perfect binding, spiral binding

Lamination - gloss, matte, or velvet touch.

special finishes - hot embossing, cold embossing, foil stamping, spot UV varnishing, thermal lamination, letterpress.

Finishing is where form meets function and your print starts to shine.

5. Quality Check & Delivery

Before your order is packed, our quality control team performs a final inspection. We check:

Color accuracy

Sharpness and registration

Paper quality and finish

Clean cuts and bind alignment

Only once everything meets our standards does it move to packaging and delivery. We use secure, eco-friendly packaging and offer reliable delivery options to deliver your prints on time and in perfect condition.

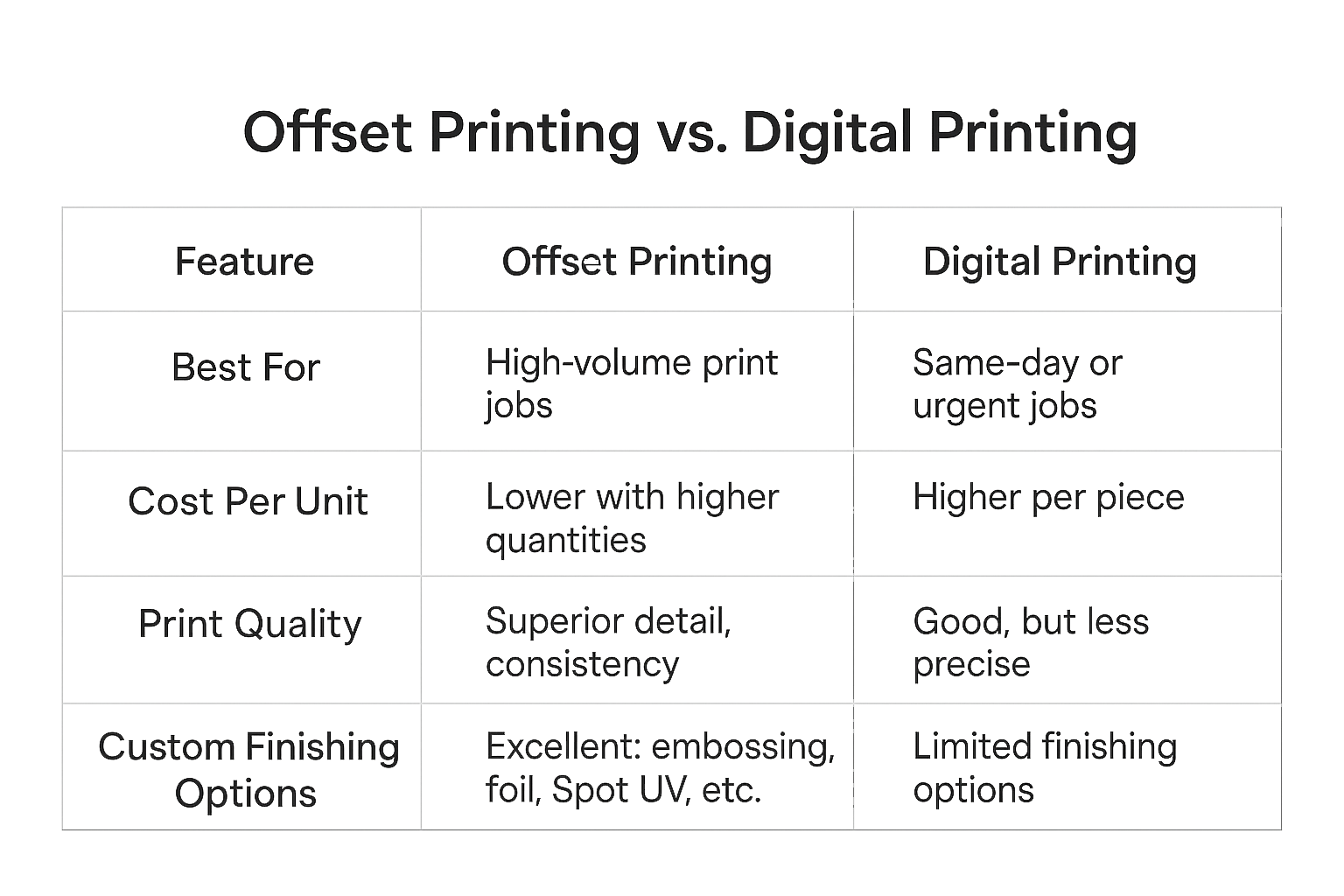

Advantages of Offset printing against digital printing: showing key differences between offset printing and digital printing

Is Offset Printing Affordable?

Yes, especially for larger quantities. Offset printing has a lower cost per unit and becomes significantly cheaper as quantity increases. That’s why it’s the most economical option for businesses printing.

Apparel Tags & Packaging

Hang tags

Folding tags

Barcode labels

Packaging inserts

Apparel Tags & Packaging made by Offset Printing with a special finishing technique called Velvet Matt Lamination.

Pharmaceutical & Medical Packaging

Product inserts

Folding cartons

Medicine boxes

Custom medical labels

Pharmaceutical & Medical Packaging of Boxes and Covers made with Offset Printing.

Business & Promotional Materials

Flyers

Notepad

Brochures

Letterheads

Business cards

Company profiles

Catalogue printing

Branded envelopes

Presentation folders

Business promotional Material made with Offset printing, like Branded letterhead design from PrintExpress.

Custom Printing

Menus

Posters

Booklets

Postcards

Invitations

Magazines

Door hangers

Gift certificates

Custom stickers

Custom Printing and binding of Calendars and Books.

So, if you're printing 500 or more, offset is always more affordable per piece.

When Should You Choose Offset?

Offset printing is the best choice when

You need large quantities.

You care about cost-efficiency and affordability.

Color consistency is critical.

You want premium finishes like Spot UV, foil, embossing, or lamination.

You’re printing on thicker or specialty paper.

If your project fits any of the above, offset is your go-to.

Why Print Express by D Karunadhara?

At Printexpress, we bring together 30+ years of industry experience, state-of-the-art offset machines, and a deeply passionate team.

What sets us apart?

We use modern, energy-efficient machinery to reduce waste and turnaround times.

Our paper comes from certified sustainable suppliers, supporting responsible forestry.

We offer 6 high-end finishing techniques for a premium, professional finish.

Offset printing continues to be the gold standard for bulk printing offering stunning results, long-term cost savings, and a level of polish that digital printing simply can’t match.

If you’re planning a large print run and care about quality, affordability, and impact offset is still the best choice.

Q: Can I print just 100 copies with offset?

Yes, but it's more cost-effective for 500+ copies.

Q: Is offset printing eco-friendly?

At Printexpress, yes! We source FSC-certified paper and use machines that minimize ink and paper waste.

Q: How long does it take?

Offset jobs by PrintExpress are completed in 2-3 days.

Ready to Print?