Paper to Prints: How Your Ideas Come to Life at Print Express.

Welcome to the first story from inside our Pre-Pressroom, where paper, passion, and precision

meet to craft prints that truly leave a mark.

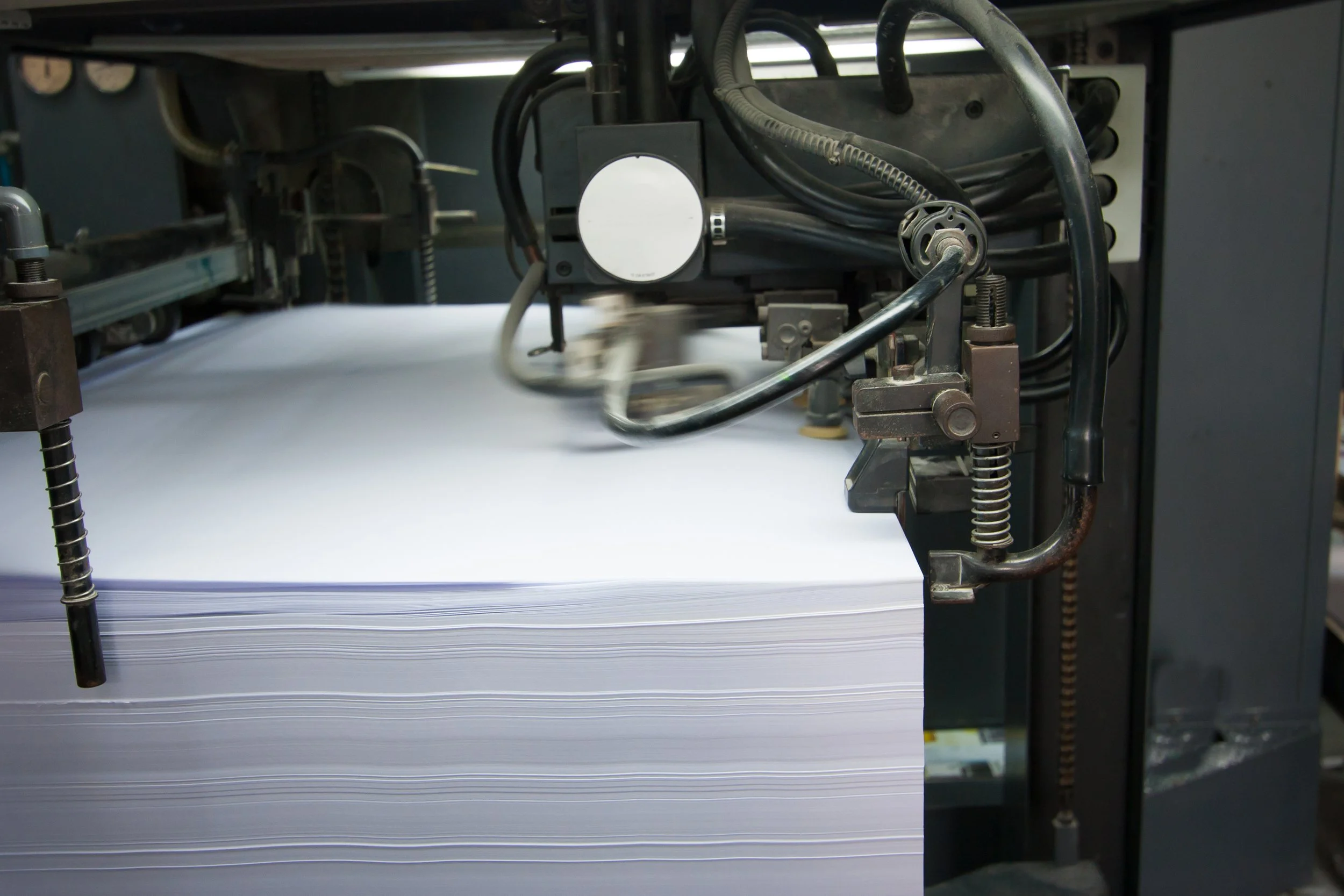

Every great print starts with something simple: a sheet of paper. We carefully select high-quality sheets tailored to your project’s needs, whether it’s sleek brochures, elegant business cards, robust apparel tags, pharmaceutical packaging, or books. Look and feel are essential to choosing the correct paper, but just as important as these physical aspects is the sourcing of the paper itself. That’s why we use only certified sustainable paper suppliers. It's our way of supporting responsible forestry and reducing our environmental footprint.

But the paper is just the beginning.

1. Design & Prepress: Preparing for Perfection

Every great print begins long before a sheet of paper touches a press. It begins with an idea, and at PrintExpress, we know that ideas arrive in many different forms.

Option 1: You Bring the Design – We Prepare It for Print

If you already have a completed design perhaps created by your own designer or agency, our Prepress team conducts a full technical review before it goes anywhere near our printing machines. This stage ensures that what looks good on a screen will also look flawless in physical form.

Here’s what we check:

Layout & Margins: Making sure all elements are properly positioned and nothing essential is too close to the edge.

Color Accuracy: Verifying that colors are set in CMYK and ensuring they convert correctly for offset printing.

Resolution: Checking that all images and graphics are high-resolution at 300 DPI or higher to avoid pixelation.

Fonts & Embeds: Ensuring all fonts are embedded or outlined to prevent missing text or unexpected font substitutions.

Bleed & Trim Lines: Confirming a proper bleed of 3mm and safe zones for cutting so that no important content gets trimmed off.

Option 2: You Bring the Idea – We Design It from Scratch

In many cases, customers come to us not with a final design but with a concept, sketch, or even just an idea. That’s where our in-house creative team steps in.

We work closely with you to understand:

Brand identity and message

Target audience

Functional goals

Preferred color schemes and typography

From there, we create a custom design we create a custom design to for your unique needs, We combine creativity with print-specific expertise to ensure every design we produce not only looks stunning but is also optimized for the offset process including proper ink trapping, overprint settings, and press-friendly color choices.

2. Offset Printing: The Heart of What We Do

At Printexpress, offset printing is at the core of everything we produce, trusted by industries ranging from retail to pharmaceuticals for its superior color fidelity, sharpness, and production efficiency.

Our Technology

We use Heidelberg Speedmaster SM 74 and Komori Lithrone S29 offset printing presses, both globally respected for their speed, precision, and robust engineering. These presses allow us to handle a wide variety of stocks and formats from lightweight book paper to thick artboards and folding cartons.

Each press is fitted with:

CIP3/CIP4 integration for automated ink presetting and color control

AutoPlate systems for quick plate changes

Closed-loop color management using spectrophotometry for real-time ink adjustments

Alcohol-free dampening systems for consistent print quality and reduced environmental impact

The Plate-Making Process

Our prepress workflow is powered by Kodak Trendsetter Q800 thermal CTP Computer-to-Plate technology. We use Fuji and Kodak aluminum plates, which are known for excellent ink receptivity and durability during long print runs.

Each job typically requires four plates, one for each CMYK color Cyan, Magenta, Yellow, and Black. If the job involves Pantone spot colors or special coatings, additional plates are prepared accordingly.

Precision in Motion

Once plates are mounted:

Our operators calibrate ink zones to exact values based on the print layout.

Registration controls ensure perfect alignment of colors across the sheet achieving the precise halftone reproduction required for photographic and brand-color accuracy.

Our machines run at speeds up to 5,000 sheets per hour with real-time monitoring to maintain consistency across the entire batch.

3. Speed, Scale & Affordability

Offset printing is where performance meets precision, especially when it comes to handling large volumes with uncompromised quality.

At Printexpress, our Heidelberg Speedmaster SM 74 and Komori Lithrone S29 offset presses are engineered for high-speed output and exacting standards. With speeds of up to 5,000 sheets per hour and automated plate-changing and ink calibration we can take on demanding jobs with speed and confidence.

Whether it’s brochures, product packaging, books, or apparel tags, offset lets us deliver high volumes in a short timeframe all while maintaining rich, consistent color and ultra-sharp details from the first sheet to the last.

What makes offset even more powerful is its cost-efficiency at scale. As your quantity increases, the cost per unit drops significantly making it the smarter choice for businesses that need both impact and value.

Our fully automated CIP3-connected workflow ensures fast setup, minimal waste, and precise color matching across runs so your project is not only delivered faster but more efficiently.

Why It Matters:

High-volume capacity with tight deadlines

Consistent quality across every sheet

Lower unit cost for medium to large print runs

Reduced waste and faster job changeovers

4. Finishing: The Final Touches

At Printexpress, we believe printing is not just about ink and paper it's about experience. Finishing is where your printed material moves from being simply informative to truly memorable. Whether it's a raised logo that catches the light, a soft-touch lamination that invites fingers to linger, or a foil stamp that radiates elegant finishing transforming your project from functional to exceptional.This is where your flat sheets are transformed into functional, beautiful, and premium products, ready to deliver impact.

That’s why we offer a diverse and carefully curated selection of professional finishing options, all done in-house, using industry-leading equipment and techniques. These finishes aren’t “extras:” they're what complete the story of your brand.

Here are the finishing options we provide:

Thermal Embossing – Tactile Brilliance

Thermal embossing enhances the physical feel of your printed piece by raising specific design elements using heat and pressure. This technique is often used to highlight logos, titles, or patterns, creating a luxurious texture that’s not only seen but also felt.

Whether you're producing high-end business cards, rigid boxes, or invitation suites, thermal embossing adds a distinctive layer of sophistication. It’s the difference between something people read and something they remember.

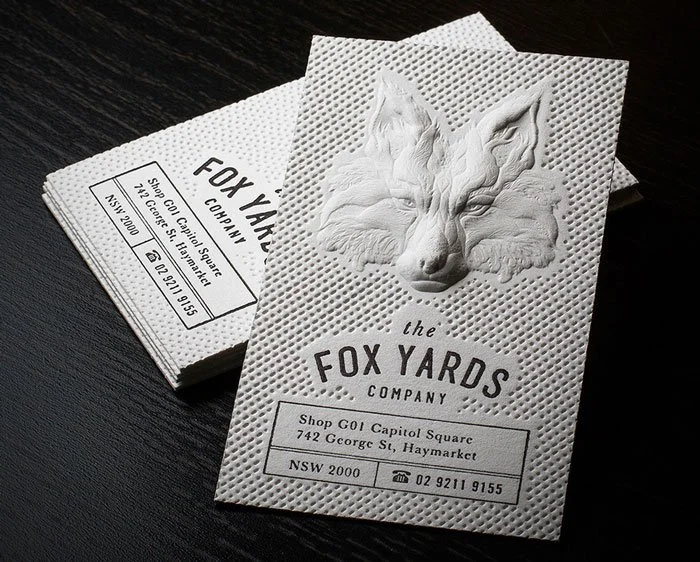

2. Blind Embossing (2D & 3D) – Understated Elegance

Unlike thermal embossing, blind embossing uses no ink or foil. It’s all about subtlety and dimension. Your design is pressed into the paper to create a clean, minimalist effect, relying solely on light and shadow for contrast.

We offer both:

2D blind embossing for a gentle, refined lift.

3D blind embossing for a more sculptural and pronounced texture.

Perfect for luxury branding, monograms, and artistic stationery, blind embossing speaks softly yet powerfully of quality.

3. Hot Foil Stamping – Luxury That Shines

Hot stamping, also known as foil stamping, involves pressing a metallic or colored foil onto paper using heat and pressure. The result is a stunning, reflective surface that instantly commands attention.

We stock a wide range of foils:

Classic gold, silver, and bronze

Rich rose gold

Custom pigmented colors

Unique holographic effects

Ideal for premium packaging, diplomas, wedding stationery, or high-end menus, hot stamping gives your design the luxurious edge it deserves.

4. Thermal Lamination – Durability & Elegant Protection

Lamination protects your print while enhancing its appearance. Using thermal lamination, we apply a thin film to the surface of the paper. This not only resists moisture, scratches, and wear, but also provides an aesthetic upgrade.

You can choose from:

Gloss lamination – for bold colors and high shine

Matte lamination – for a smooth, elegant look

Soft-touch lamination – for a velvety, premium feel

This technique is essential for items like product boxes, restaurant menus, brochures, and labels that must endure handling without losing their appeal.

5. Spot UV Coating – Shine with Precision

Spot UV is a targeted application of high-gloss coating applied only to specific areas of your design usually over a matte background. It creates a stunning contrast of textures that draws the eye exactly where you want it.

This finish is especially effective on:

Business cards

Brochures

Retail packaging

Product tags

From a design perspective, Spot UV is a brilliant way to make your logos, icons, and titles stand out with subtle drama.

6. Letterpress Printing – Classic Craftsmanship

Letterpress is a centuries-old printing technique that presses ink into the paper, creating a visible and tangible impression. It’s a blend of precision and nostalgia in style that speaks of tradition, artistry, and permanence.

We use letterpress for:

Wedding and event invitations

Certificates and awards

High-end stationery

Each print has its own texture and depth, offering a unique sensory experience that digital methods simply can't replicate.

5. Quality Check and Delivery.

Printing isn’t complete until we’ve ensured that every single copy reflects the standard we’re known for. That’s where our quality control process comes in the final checkpoint before your product reaches your hands.

Our dedicated quality assurance team performs a meticulous inspection of each job, checking for:

Color Consistency – Are the hues accurate across the entire run? We compare outputs to the original design and Pantone specs.

Image Sharpness – Are details crisp and clean? We zoom in on the fine print.

Registration & Alignment – Are all layers of color perfectly aligned? Precision matters here.

Finishing Accuracy – Are the cuts clean? Is the embossing perfectly placed? Is the lamination bubble-free?

Only once a job meets our exacting standards does it move to the packing and delivery phase.

We use secure, professional-grade packaging tailored to each order size whether you’re getting a stack of business cards or a thousand hardcover books. We make sure your prints are protected in transit and arrive in pristine condition.

To us, your final unboxing moment isn’t just a delivery It’s a part of our legacy

.

At PrintExpress, printing is not just a Business; it's a legacy.

Our story began over 30 years ago, when our founder, Mr. Dammika Karunadhara, opened a modest press driven by one belief: that every printed piece should carry the same pride as a signature. What started as a small print shop serving local businesses has since evolved into one of Sri Lanka’s most trusted names in offset printing, known for quality, precision, and service.

From the early days, hand-setting type and managing analog plate systems, to now operating state-of-the-art offset machines, one thing has remained unchanged: Our dedication to excellence in print.

What started as a small family-run operation has grown into one of Sri Lanka’s most respected names in the industry, trusted by corporates, creatives, and entrepreneurs alike. We’ve embraced new technologies and expanded our capabilities, but we’ve never lost the soul of our work. We still believe that every print tells a story and that story deserves to be told beautifully.

From concept to color, paper texture to packaging, every project we take on is treated with the same care and attention to detail. Whether it’s a luxury box, a perfectly bound publication, or a simple business card, if it carries your name, it carries our reputation. That’s why we continue to invest in:

Sustainability – sourcing certified eco-friendly paper, minimizing waste, and using energy-efficient equipment.

Technology – operating high-speed offset presses capable of large volumes with unmatched color control.

Detail – from CMYK plate calibration to specialty finishing like embossing, foiling, spot UV, and letterpress every element matters.

Our clients range from corporate giants and national brands to designers, startups, publishers, and individuals but the level of care we bring to each project remains the same.

at Printexpress, we don’t just print what’s on your file

We bring your vision to life.

And after three decades, we’re still just getting started.

Printexpress by D. Karunadhara

Crafted to Impress